Zero Liquid Discharge (ZLD): Is It Right for Your Industry?

Feb 13, 2026

uploads/blogs/blog_698eae5540c30.jpg

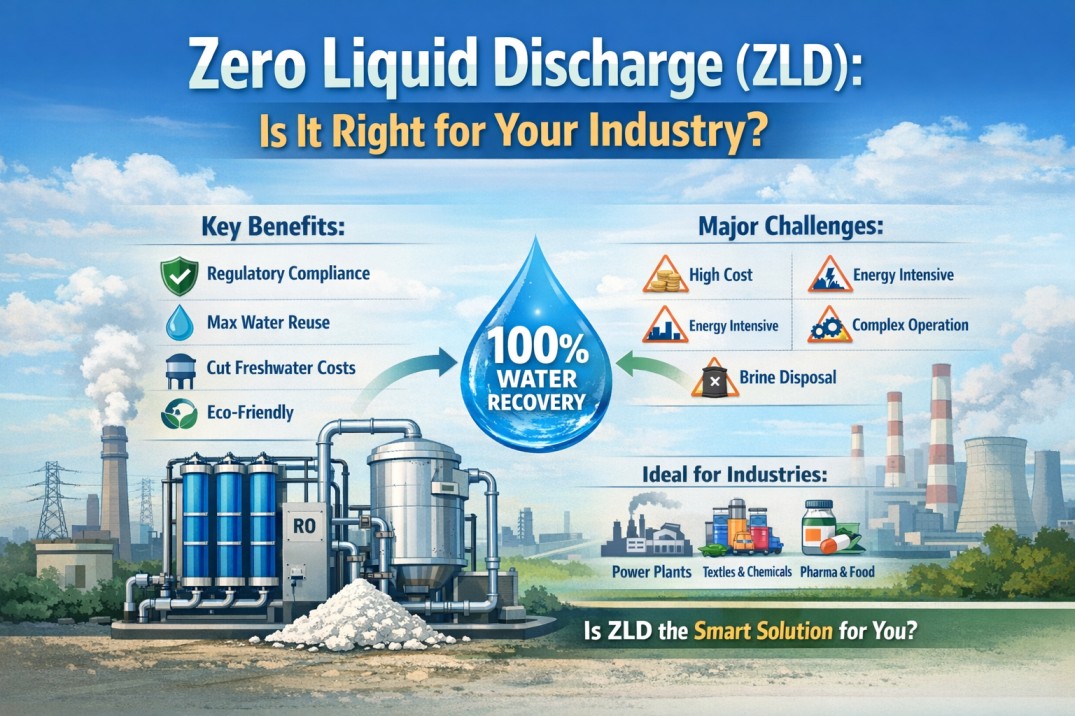

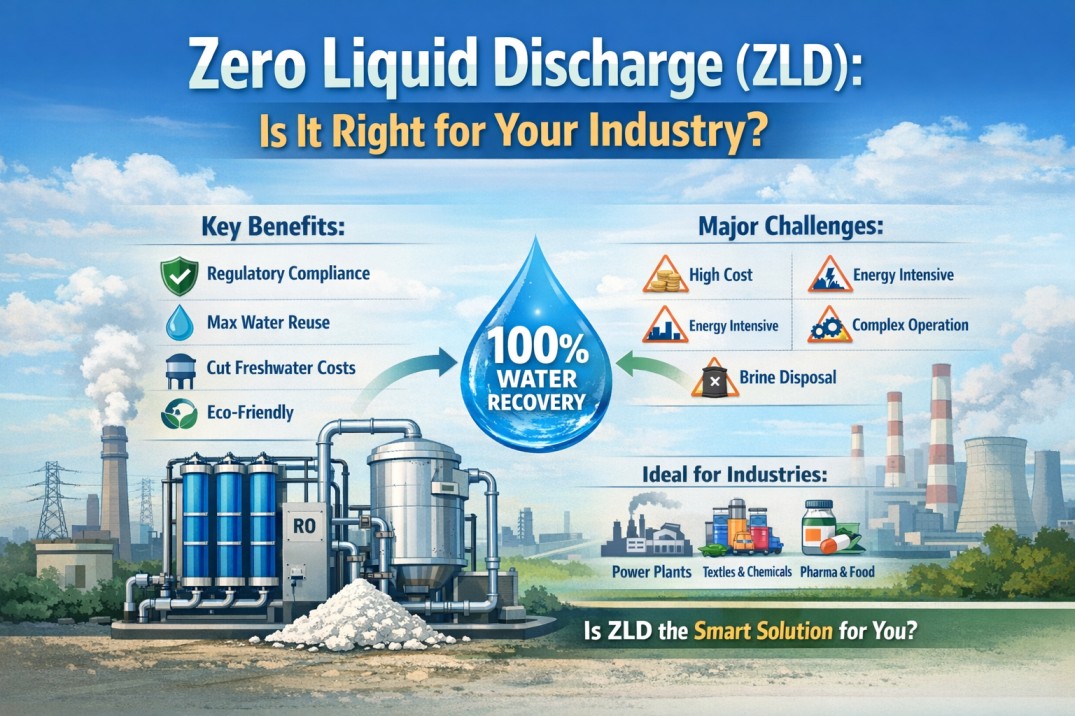

A Zero Liquid Discharge system is a comprehensive wastewater treatment approach that:

✔ Recovers reusable water

✔ Converts dissolved solids into solid waste

✔ Prevents any liquid effluent discharge

Instead of releasing treated water into drains, ZLD recycles it back into operations.

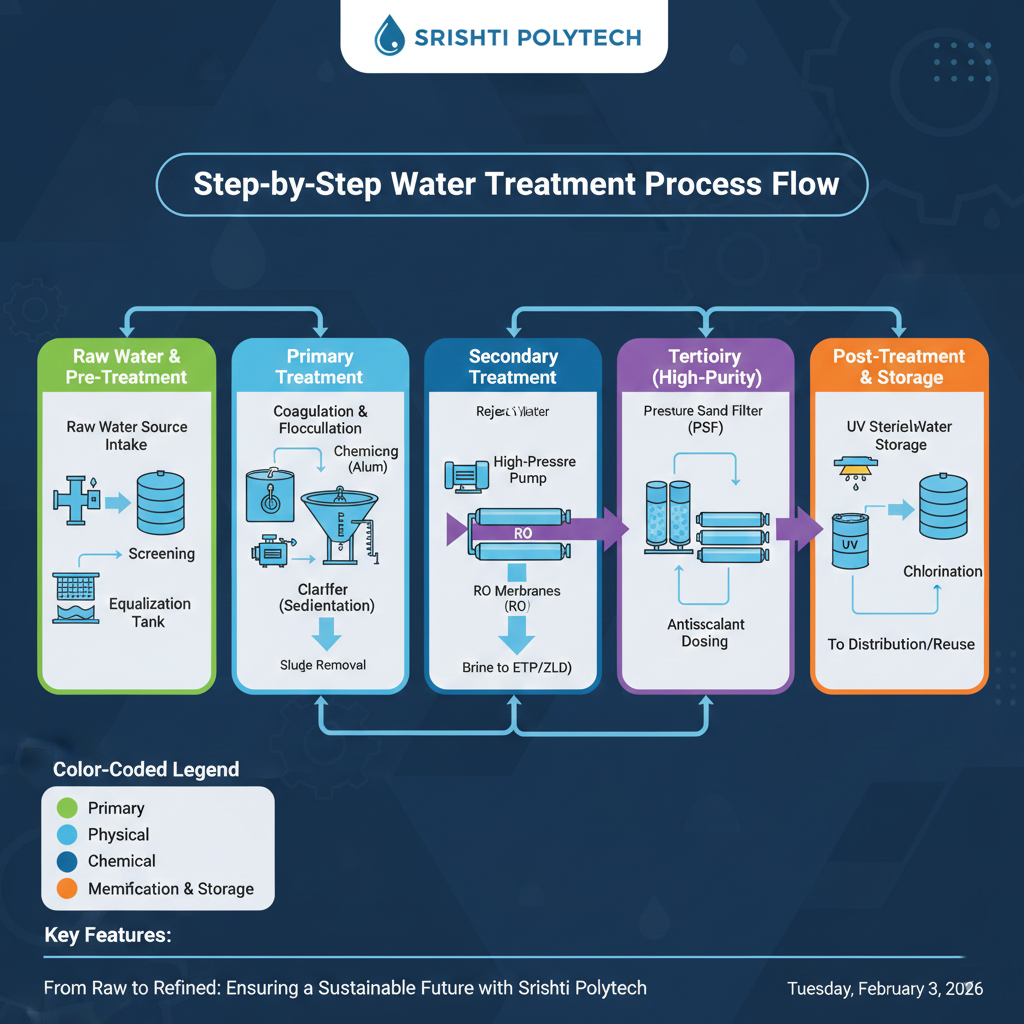

How Does a ZLD Plant Work?

A typical ZLD process flow includes:

Pre-treatment / Effluent Treatment Plant (ETP)

Removal of suspended solids, oil, organics

Membrane Separation

UF / RO systems recover clean water

Concentrates reject stream

Evaporation / Crystallization

Thermal evaporation of brine

Salt recovery / solid waste formation

Water Reuse

Recovered water reused in cooling, boilers, washing

Industries That Commonly Use ZLD

ZLD is particularly valuable where:

Water consumption is high

Effluent discharge norms are strict

Raw water cost is rising

Typical sectors:

✔ Power plants

✔ Textile & dyeing units

✔ Pharmaceuticals

✔ Chemicals & petrochemicals

✔ Food & beverage processing

✔ Tanneries

✔ Electronics & semiconductor

Benefits of a ZLD System

1. Regulatory Compliance

Meets stringent pollution control board norms.

2. Maximum Water Recovery

Up to 95–99% water reuse possible.

3. Reduced Freshwater Dependency

Critical in water-scarce regions.

4. Environmental Protection

Prevents contamination of soil & water bodies.

5. Long-Term Cost Control

Savings on water procurement & discharge penalties.

Challenges to Consider

While ZLD offers major advantages, it’s not a universal fit.

⚠ High Capital Investment

Includes RO + evaporator + crystallizer.

⚠ Energy Intensive

Thermal evaporation consumes power/steam.

⚠ Operational Complexity

Requires skilled operation & maintenance.

⚠ Brine/Salt Disposal

Recovered solids must be handled responsibly.

When Does ZLD Make Financial Sense?

A ZLD plant becomes viable when:

✔ Discharge penalties are high

✔ Water costs are rising

✔ Freshwater availability is limited

✔ Regulatory pressure is strict

✔ Effluent volumes are large

Key Questions Before Investing in ZLD

Ask yourself:

1️⃣ What is your daily wastewater generation?

2️⃣ What are your discharge compliance risks?

3️⃣ How expensive is fresh/raw water?

4️⃣ Do you have energy capacity for evaporation?

5️⃣ Can recovered water be reused internally?

Alternatives to Full ZLD

If full ZLD seems excessive:

✔ High-recovery RO systems

✔ Partial recycle & reuse

✔ Advanced ETP with tertiary treatment

✔ Evaporator-only concentration

Expert Recommendation

ZLD is not just a treatment system — it’s a strategic sustainability decision.

It’s ideal for industries facing:

✔ Severe water scarcity

✔ Strict environmental regulations

✔ Large-scale wastewater discharge

But smaller operations may benefit from optimized recycling solutions instead of full ZLD.

Conclusion

A Zero Liquid Discharge system can transform wastewater from a liability into a resource — but only when aligned with technical feasibility, compliance needs, and ROI considerations.

Careful evaluation is essential.

Need Help Deciding?

At Srishti Polytech, we design:

✅ ZLD plants

✅ Effluent Treatment Plants (ETP)

✅ RO-based water recovery systems

✅ Customized recycle & reuse solutions

📞 Contact us for a feasibility assessment tailored to your industry.

Feb 13, 2026

Zero Liquid Discharge (ZLD): Is It Right for Your Industry?

A Zero Liquid Discharge system is a comprehensive wastewater treatment approach that:

✔ Recovers reusable water

✔ Converts dissolved solids into solid...

Why TDS Matters in Industrial Water Treatment | TDS Control Guide

Feb 11, 2026

uploads/blogs/blog_698c1c5aee708.jpg

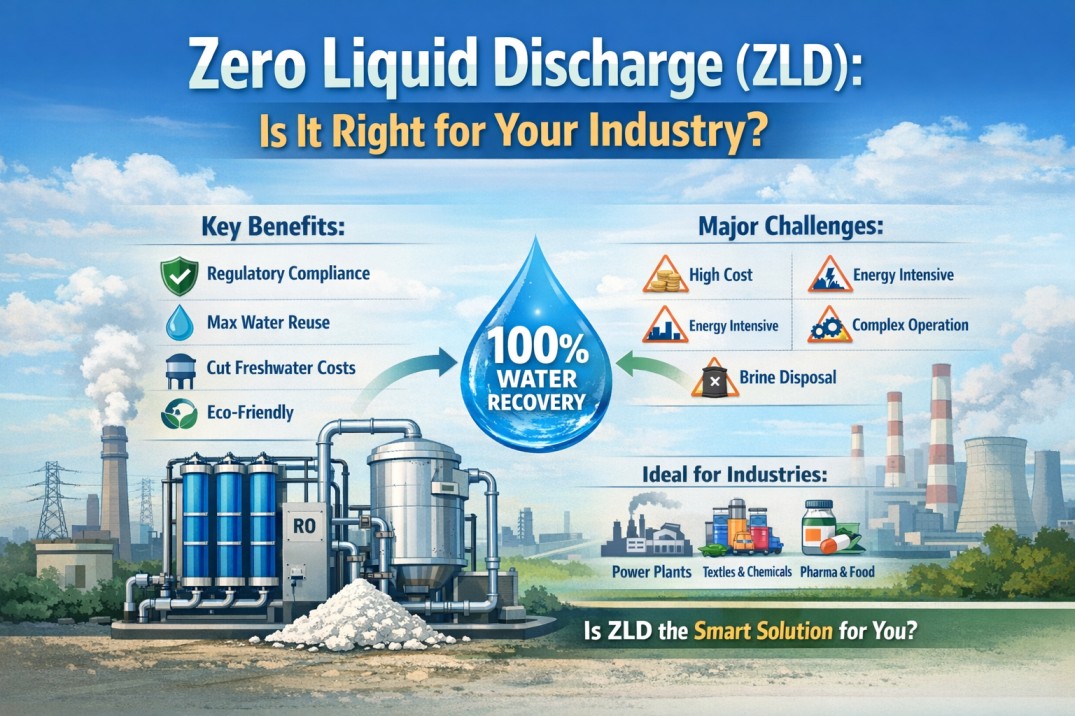

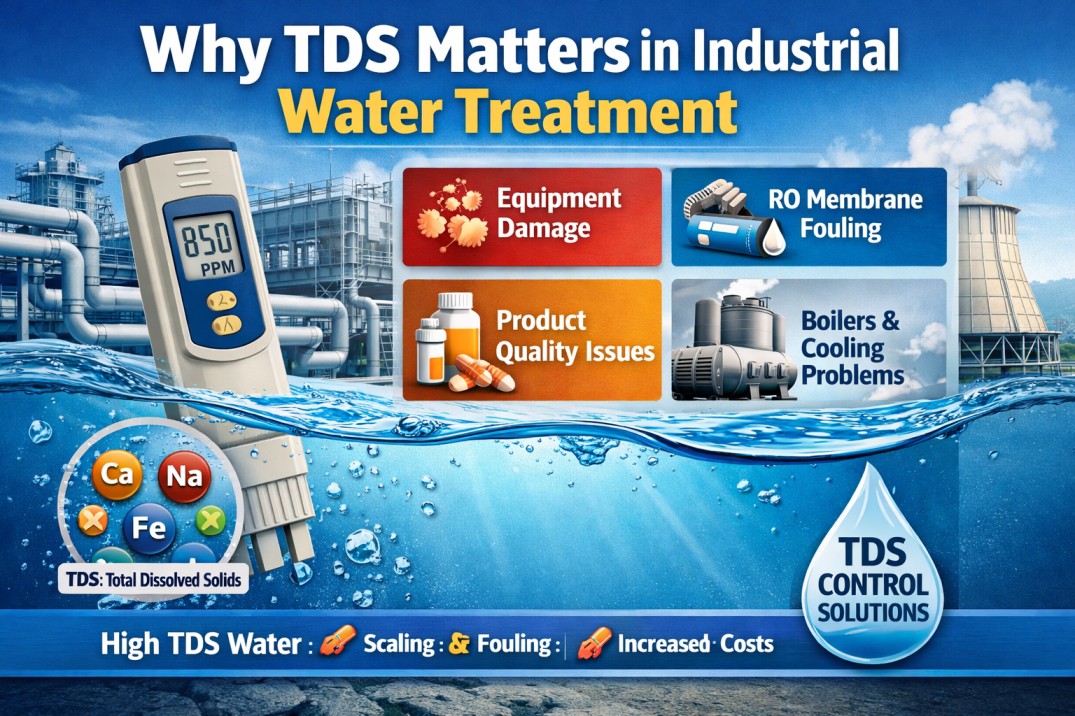

What is TDS (Total Dissolved Solids)?

Total Dissolved Solids (TDS) refers to the concentration of dissolved substances present in water, including:

✔ Minerals (calcium, magnesium, sodium)

✔ Salts

✔ Metals

✔ Organic matter

TDS is typically measured in ppm (parts per million) and directly indicates water quality.

Why TDS is Important in Industrial Water Treatment

In industrial water treatment, TDS plays a crucial role in:

🔹 1. Equipment Protection

High TDS water can cause:

❌ Scaling in boilers

❌ Fouling of heat exchangers

❌ Membrane clogging in RO plants

❌ Corrosion in pipelines

Result: Reduced efficiency & costly downtime.

🔹 2. RO Plant Performance

An industrial RO plant is designed to reduce TDS, but:

Extremely high TDS → Faster membrane fouling

Poor pretreatment → Reduced rejection rate

Uncontrolled TDS → Higher operating cost

👉 Proper TDS control improves RO plant lifespan.

🔹 3. Product Quality

Industries requiring controlled TDS:

✔ Pharmaceuticals

✔ Food & Beverage

✔ Textiles

✔ Electronics

✔ Chemical manufacturing

High TDS can affect:

Taste

Chemical reactions

Surface finish

Process stability

🔹 4. Boiler & Cooling System Efficiency

High TDS leads to:

❌ Scale formation

❌ Heat transfer loss

❌ Increased fuel consumption

👉 Maintaining optimal TDS reduces energy waste.

Problems Caused by High TDS Water

Issue Industrial Impact

Scaling Reduced heat transfer

Corrosion Equipment damage

Membrane Fouling RO failure

Product Defects Quality rejection

Increased Chemical Usage Higher costs

Ideal TDS Levels for Industrial Use

Different applications require different TDS ranges:

Boiler Feed Water: Very low TDS

Cooling Towers: Controlled TDS cycles

Process Water: Application specific

Drinking / Packaged Water: As per standards

How to Control TDS in Industrial Water

✅ 1. Reverse Osmosis (RO Plant)

Best for TDS reduction and desalination.

✅ 2. Deionization (DI System)

For ultra-pure water applications.

✅ 3. Water Softener

Prevents scaling but does not reduce TDS significantly.

✅ 4. Proper Pretreatment

Sand filter, carbon filter, antiscalant dosing.

Why Industries Must Monitor TDS Regularly

Continuous monitoring helps:

✔ Prevent membrane damage

✔ Maintain compliance

✔ Optimize chemical dosing

✔ Improve plant efficiency

👉 Ignoring TDS = Increased operational cost

Conclusion

TDS in industrial water is not just a number — it directly affects:

✔ Equipment life

✔ Energy consumption

✔ RO plant performance

✔ Final product quality

Investing in the right industrial water treatment solution ensures:

✅ Lower maintenance costs

✅ Higher efficiency

✅ Consistent water quality

Need Help with High TDS Water?

If your industry faces:

❌ Scaling issues

❌ RO membrane failures

❌ Poor water quality

👉 A properly designed Industrial RO Plant / Water Treatment System can solve it.

Feb 11, 2026

Why TDS Matters in Industrial Water Treatment | TDS Control Guide

What is TDS (Total Dissolved Solids)?

Total Dissolved Solids (TDS) refers to the concentration of dissolved substances present in water, including:

✔...

How Proper RO Plant Maintenance Ensures Long-Term System Performance

Feb 10, 2026

uploads/blogs/blog_698ac352cf263.jpg

An RO (Reverse Osmosis) plant is a long-term investment for industries, commercial buildings, hospitals, and institutions. However, without proper RO plant maintenance, even the best-designed system can suffer from reduced performance, high operating costs, and frequent breakdowns.

Regular maintenance not only improves water quality but also extends membrane life, reduces downtime, and lowers overall costs. In this blog, Srishti Polytech, a trusted RO plant manufacturer in India, shares a complete RO plant maintenance checklist to ensure long-term, trouble-free performance.

Why RO Plant Maintenance Is Critical

Proper RO plant servicing helps to:

Maintain consistent water quality

Prevent membrane fouling and scaling

Reduce power and chemical consumption

Avoid sudden system failures

Increase RO membrane life

Meet industry and regulatory standards

Neglecting maintenance often leads to low recovery, high TDS in permeate, increased rejection rates, and expensive replacements.

RO Plant Maintenance Checklist (Step-by-Step)

1️⃣ Daily RO Plant Maintenance Checklist

✔ Check raw water pressure and flow rate

✔ Monitor inlet and outlet TDS values

✔ Inspect pressure drop across filters

✔ Check pump noise, vibration, and leakage

✔ Ensure no leakage in piping and fittings

✔ Verify electrical panel indicators

👉 Tip: Sudden pressure or TDS variation is an early sign of membrane fouling.

2️⃣ Pre-Treatment System Maintenance

Pre-treatment is the backbone of industrial RO plant maintenance.

✔ Clean or backwash Multigrade Filter (MGF)

✔ Backwash Activated Carbon Filter (ACF) regularly

✔ Check media condition (sand, gravel, carbon)

✔ Inspect softener resin and salt level

✔ Verify iron and turbidity levels

🔴 Poor pre-treatment is the number one cause of RO membrane failure.

3️⃣ Cartridge Filter Maintenance

✔ Inspect cartridge filters daily

✔ Replace cartridges when pressure drop increases

✔ Typical replacement cycle: 7–30 days (depends on feed water quality)

Using clogged cartridge filters leads to membrane damage and pump overload.

4️⃣ RO Membrane Maintenance Checklist

✔ Monitor permeate flow and salt rejection

✔ Check differential pressure across membranes

✔ Perform chemical cleaning (CIP) when required

✔ Avoid chlorine exposure to membranes

✔ Use recommended antiscalant dosing

📌 RO membrane cleaning should be done when:

Permeate flow drops by 10–15%

Pressure drop increases by 15–20%

Salt rejection decreases

5️⃣ Chemical Dosing System Maintenance

✔ Check antiscalant dosing pump operation

✔ Ensure correct chemical concentration

✔ Inspect dosing lines and NRVs

✔ Calibrate dosing pumps periodically

Incorrect dosing causes scaling, fouling, and membrane choking.

6️⃣ High-Pressure Pump Maintenance

✔ Check pump alignment and vibration

✔ Inspect mechanical seals and bearings

✔ Lubricate as per manufacturer guidelines

✔ Monitor motor current and temperature

Regular pump maintenance ensures energy efficiency and system stability.

7️⃣ Electrical & Control Panel Inspection

✔ Check contactors, relays, and wiring

✔ Inspect overload and short-circuit protection

✔ Test pressure switches and sensors

✔ Ensure proper earthing

Electrical issues are a major reason for unexpected RO plant shutdowns.

8️⃣ RO Plant Cleaning & Sanitization

✔ Sanitize RO system periodically

✔ Flush membranes after long shutdowns

✔ Prevent biofouling in storage tanks

✔ Maintain hygienic permeate pipelines

Sanitization is especially critical for drinking water, hospitals, and food industries.

9️⃣ Record Keeping & Performance Log

✔ Maintain daily log sheets

✔ Record pressure, flow, TDS, and recovery

✔ Track filter replacement and CIP history

✔ Analyze trends to predict failures

Good documentation improves preventive maintenance planning.

Recommended RO Plant Maintenance Schedule

Component Maintenance Frequency

Pre-filters Daily / Weekly

Cartridge filters 7–30 days

RO membranes 6–12 months (cleaning)

Pumps & motors Monthly

Electrical panel Quarterly

Full system audit Annually

Importance of RO Plant AMC (Annual Maintenance Contract)

Opting for a professional RO Plant AMC ensures:

Scheduled preventive maintenance

Priority breakdown support

Reduced operating cost

Longer equipment life

Consistent water quality

Srishti Polytech offers customized RO plant AMC services for industrial and commercial clients across India.

Why Choose Srishti Polytech for RO Plant Maintenance?

✔ OEM manufacturer support

✔ Experienced service engineers

✔ Genuine spare parts & membranes

✔ Customized maintenance plans

✔ Fast response & technical expertise

As a trusted RO plant manufacturer and service provider, we design and maintain systems for industries, hospitals, hotels, railways, and institutions.

Conclusion

A well-maintained RO plant delivers consistent performance, high-quality water, and long-term cost savings. Following this RO plant maintenance checklist and partnering with an experienced OEM like Srishti Polytech ensures your system operates at peak efficiency for years.

Call to Action (CTA)

📞 Need RO Plant Maintenance or AMC?

🌐 Visit: www.srishtipolytech.com

📧 Contact us for industrial RO plant servicing, upgrades, and AMC solutions.

Feb 10, 2026

How Proper RO Plant Maintenance Ensures Long-Term System Performance

An RO (Reverse Osmosis) plant is a long-term investment for industries, commercial buildings, hospitals, and institutions. However, without proper RO...

Iron Removal Plant – Working Principle, Benefits & Applications | Srishti Polytech

Feb 07, 2026

uploads/blogs/blog_6986d49cf0ab6.jpg

Iron Removal Plant: Working Principle, Benefits & Applications

Groundwater contamination with excess iron is a common problem across many regions in India. High iron content causes reddish-brown stains, metallic taste, pipeline choking, and damage to industrial equipment. An Iron Removal Plant (IRP) is an effective water treatment solution designed to remove dissolved and suspended iron from water, making it safe for domestic, commercial, and industrial use.

What Is an Iron Removal Plant?

An Iron Removal Plant is a water treatment system that removes iron (Fe²⁺ / Fe³⁺) from groundwater using oxidation, filtration, and adsorption processes. It improves water quality by eliminating iron particles, odor, discoloration, and turbidity.

Iron removal systems are widely used in:

Drinking water treatment

Industrial water supply

Rural and municipal water schemes

Pre-treatment for RO plants

Working Principle of an Iron Removal Plant

The working of an iron removal plant involves multiple stages:

1. Oxidation

Dissolved ferrous iron (Fe²⁺) is oxidized into ferric iron (Fe³⁺) using:

Aeration

Chlorination

Chemical oxidants (as per water quality)

Oxidized iron converts into insoluble iron particles.

2. Filtration

The oxidized iron particles are removed by passing water through a pressure filter containing specialized media such as:

Manganese dioxide

Birm media

Sand and gravel layers

3. Backwashing

Accumulated iron sludge is flushed out through periodic backwashing, ensuring consistent performance and long filter life.

Benefits of an Iron Removal Plant

✅ Removes excess iron effectively from groundwater

✅ Improves taste, color, and odor of water

✅ Prevents staining of pipelines, tanks, and fixtures

✅ Protects RO membranes and industrial equipment

✅ Low operating and maintenance cost

✅ Environment-friendly and chemical-efficient solution

Applications of Iron Removal Plants

Iron removal plants are used across multiple sectors:

🏭 Industrial Applications

Textile and dyeing industries

Food and beverage processing units

Pharmaceutical manufacturing

Boiler feed and cooling water treatment

🏘️ Domestic & Commercial Use

Residential apartments and housing societies

Hotels, hospitals, and schools

Commercial complexes and offices

🚰 Municipal & Rural Water Supply

Panchayat water supply schemes

Government drinking water projects

Community water treatment systems

Iron Removal Plant Capacity & Customization

Iron removal plants are available in various capacities, ranging from:

Small domestic units

Commercial systems (500–10,000 LPH)

Large industrial plants (customized flow rates)

Systems can be designed in FRP, MS, or SS vessels based on application, budget, and site conditions.

Why Choose Srishti Polytech for Iron Removal Plants?

Srishti Polytech is a trusted Iron Removal Plant manufacturer and supplier in India, offering:

Customized system design

High-quality filtration media

CPCB-compliant solutions

Installation and after-sales support

Cost-effective and durable plants

We provide complete solutions from design to commissioning for industrial and drinking water applications.

Conclusion

An Iron Removal Plant is an essential water treatment solution for areas affected by high iron content in groundwater. With proper design and filtration technology, it ensures clean, safe, and iron-free water for long-term use. Choosing the right manufacturer ensures efficiency, durability, and compliance with water quality standards.

Feb 07, 2026

Iron Removal Plant – Working Principle, Benefits & Applications | Srishti Polytech

Iron Removal Plant: Working Principle, Benefits & Applications

Groundwater contamination with excess iron is a common problem across many regions in...

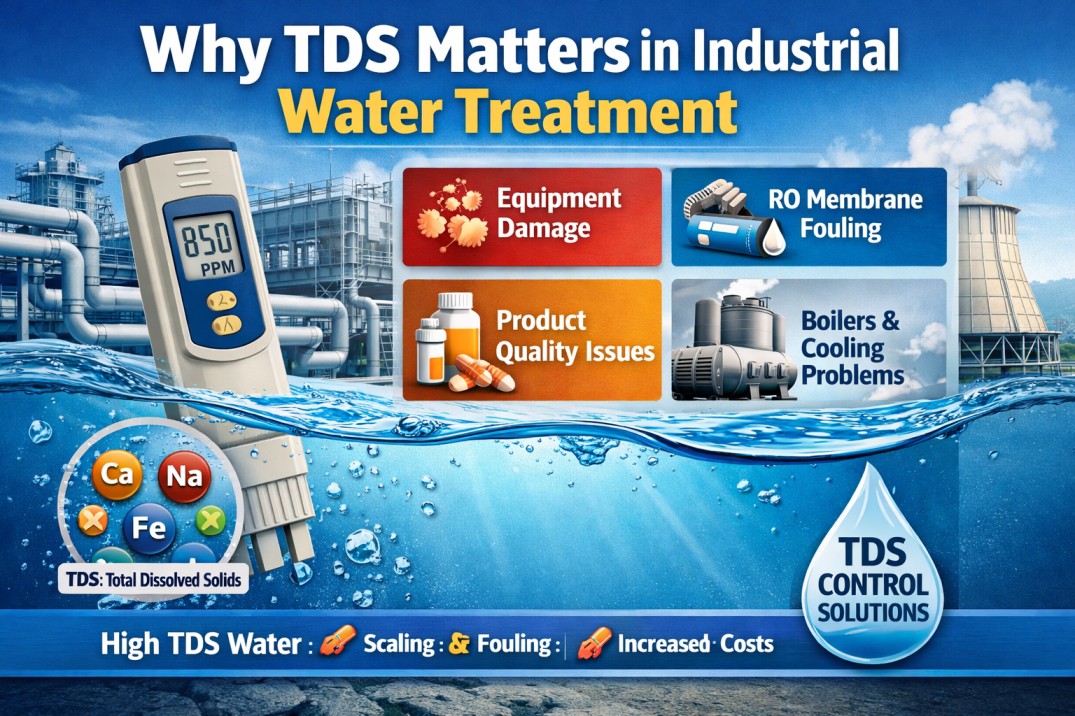

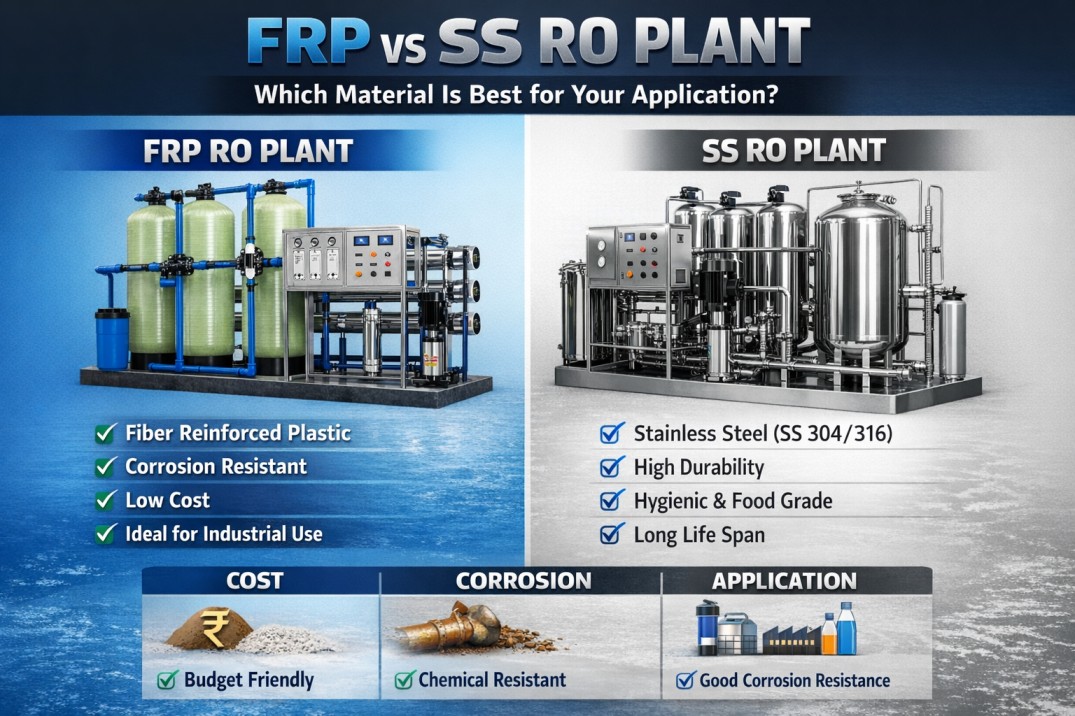

FRP vs SS RO Plant: Which Material Is Best for Your Application?

Feb 05, 2026

uploads/blogs/blog_698440cdcf98a.jpg

Choosing the right RO plant material is one of the most important decisions while setting up an industrial or commercial reverse osmosis system. The two most commonly used materials are FRP (Fiber Reinforced Plastic) and SS (Stainless Steel).

Each has its own advantages, limitations, and ideal applications. In this blog, we’ll compare FRP vs SS RO plants in detail to help you select the best option for your industry.

What Is an FRP RO Plant?

An FRP RO plant uses Fiber Reinforced Plastic for pressure vessels, pipelines, and structural components. FRP is lightweight, corrosion-resistant, and cost-effective, making it widely popular in industrial water treatment.

Key Features of FRP RO Plants

High corrosion resistance

Lightweight and easy to install

Lower initial cost

Ideal for high TDS and chemical environments

What Is an SS RO Plant?

An SS RO plant is fabricated using Stainless Steel (SS 304 or SS 316). These plants are known for their durability, hygiene, and premium finish, making them suitable for food-grade and pharmaceutical applications.

Key Features of SS RO Plants

Excellent mechanical strength

Hygienic and easy to sanitize

Long service life

High aesthetic and professional appearance

FRP vs SS RO Plant – Detailed Comparison

Parameter FRP RO Plant SS RO Plant

Material Fiber Reinforced Plastic Stainless Steel (304 / 316)

Corrosion Resistance Excellent Very good (SS 316 best)

Initial Cost Low High

Weight Lightweight Heavy

Maintenance Low Moderate

Chemical Compatibility Very high Limited for strong acids

Hygiene Moderate Excellent

Appearance Industrial Premium

Life Span 10–15 years 15–25 years

Best For Industrial & utility water Food, pharma & hospitals

When to Choose an FRP RO Plant?

An FRP RO plant is the best choice when:

Feed water has high TDS, iron, or chemical content

Budget is a key concern

Application is industrial or utility-based

Corrosion resistance is more important than appearance

Ideal Applications

Power plants

Mining industries

Steel and cement plants

Textile industries

Boiler feed water systems

Effluent recycling plants

When to Choose an SS RO Plant?

An SS RO plant is recommended when:

Water quality must meet hygienic standards

The system is exposed to public or regulated environments

Long-term durability is required

Cleanability and aesthetics matter

Ideal Applications

Pharmaceutical industries

Food & beverage plants

Bottling plants

Hospitals & laboratories

Electronics & semiconductor industries

FRP vs SS RO Plant: Cost Comparison

FRP RO Plant: 25–40% cheaper than SS systems

SS RO Plant: Higher upfront cost but longer lifespan

💡 For industries with tight budgets and harsh water conditions, FRP offers better ROI. For regulated sectors, SS is a compliance-driven choice.

Which Is Better – FRP or SS RO Plant?

There is no single “best” material—the right choice depends on:

Water chemistry

Industry standards

Budget

Hygiene requirements

Operating environment

Quick Recommendation

Industrial & utility water → ✅ FRP RO Plant

Food, pharma & healthcare → ✅ SS RO Plant

Why Choose Srishti Polytech?

At Srishti Polytech, we manufacture and supply both FRP and SS RO plants tailored to your application.

What We Offer

OEM-manufactured RO systems

Capacity range: 100 LPH to 1,00,000 LPH

Custom design as per water analysis

Compliance with BIS & industry standards

PAN India supply and service support

📞 Need help selecting FRP or SS RO plant? Our experts will guide you with the right technical recommendation.

Feb 05, 2026

FRP vs SS RO Plant: Which Material Is Best for Your Application?

Choosing the right RO plant material is one of the most important decisions while setting up an industrial or commercial...

Effluent Treatment Plant (ETP): Complete Guide by Srishti Polytech

Feb 04, 2026

uploads/blogs/blog_6983198ab866b.jpg

Introduction to Effluent Treatment Plant (ETP)

With rapid industrial growth, wastewater treatment has become a critical requirement for industries across India. An Effluent Treatment Plant (ETP) is designed to treat industrial wastewater and make it safe for discharge or reuse, as per Pollution Control Board (PCB) norms.

At Srishti Polytech, we specialize in designing, manufacturing, supplying, and installing customized Effluent Treatment Plants for various industries, ensuring environmental compliance and sustainable water management.

What is an Effluent Treatment Plant?

An Effluent Treatment Plant (ETP) is a system used to treat wastewater generated from industrial processes such as:

• Chemical industries

• Pharmaceutical industries

• Food & beverage units

• Textile and dyeing industries

• Hospitals and laboratories

• Hotels and commercial facilities

The primary goal of an ETP is to remove harmful pollutants, reduce BOD, COD, TSS, oil & grease, and ensure treated water meets CPCB / SPCB discharge standards.

Importance of Effluent Treatment Plant

Installing an ETP system is not just a regulatory requirement—it is a responsible step toward environmental protection.

Key Benefits of ETP:

• Compliance with Pollution Control Board norms

• Reduction in environmental pollution

• Water recycling and reuse

• Cost savings on fresh water consumption

• Improved corporate environmental responsibility

Effluent Treatment Plant Process Flow

A standard Effluent Treatment Plant process consists of the following stages:

1. Preliminary Treatment

• Screening chamber

• Oil & grease trap

• Equalization tank

2. Primary Treatment

• pH correction (acid/alkali dosing)

• Coagulation and flocculation

• Primary clarifier for sludge removal

3. Secondary (Biological) Treatment

• Aeration tank (Activated Sludge Process / MBBR)

• Secondary clarifier

• Reduction of BOD and COD

4. Tertiary Treatment

• Pressure Sand Filter (PSF)

• Activated Carbon Filter (ACF)

• Advanced filtration / disinfection

5. Sludge Treatment

• Sludge thickener

• Filter press / sludge dewatering system

Types of Effluent Treatment Plants We Offer

At Srishti Polytech, we provide customized ETP solutions based on industry type and wastewater characteristics:

• Chemical ETP Plant

• Pharmaceutical ETP Plant

• Textile ETP Plant

• Food Processing ETP Plant

• Hospital Effluent Treatment Plant

• CETP (Common Effluent Treatment Plant)

Why Choose Srishti Polytech for Effluent Treatment Plant?

Srishti Polytech is a trusted name in water and wastewater treatment solutions with years of industry experience.

Our Key Strengths:

• Customized ETP design as per client requirement

• Use of high-quality MS / SS / FRP materials

• Energy-efficient and low-maintenance systems

• End-to-end solutions: design, supply, installation & commissioning

• AMC and operational support

Proprietor: Raj Kumar Pandey

Firm Name: Srishti Polytech

ETP Capacity Available

We design and manufacture Effluent Treatment Plants from:

• 5 KLD

• 10 KLD

• 25 KLD

• 50 KLD

• 100 KLD

• 200 KLD and above

All plants are designed as per CPCB & SPCB guidelines.

Effluent Treatment Plant Cost in India

The cost of an Effluent Treatment Plant depends on:

• Effluent characteristics (BOD, COD, pH, TDS)

• Treatment capacity (KLD)

• Process technology

• Automation level

• Material of construction

For the best ETP price in India, contact Srishti Polytech for a customized quotation.

Applications of Effluent Treatment Plant

• Industrial wastewater treatment

• Zero Liquid Discharge (ZLD) systems

• Water reuse for gardening, cooling, and flushing

• Environmental compliance for industries

Conclusion

An Effluent Treatment Plant (ETP) is essential for industries aiming for sustainable growth and legal compliance. With rising environmental regulations, choosing the right ETP manufacturer and supplier is crucial.

Srishti Polytech, under the leadership of Raj Kumar Pandey, delivers reliable, efficient, and cost-effective Effluent Treatment Plant solutions across India.

Contact us today to get expert guidance and the best ETP solution for your industry.

Feb 04, 2026

Effluent Treatment Plant (ETP): Complete Guide by Srishti Polytech

Introduction to Effluent Treatment Plant (ETP)

With rapid industrial growth, wastewater treatment has become a critical requirement for industries across India....

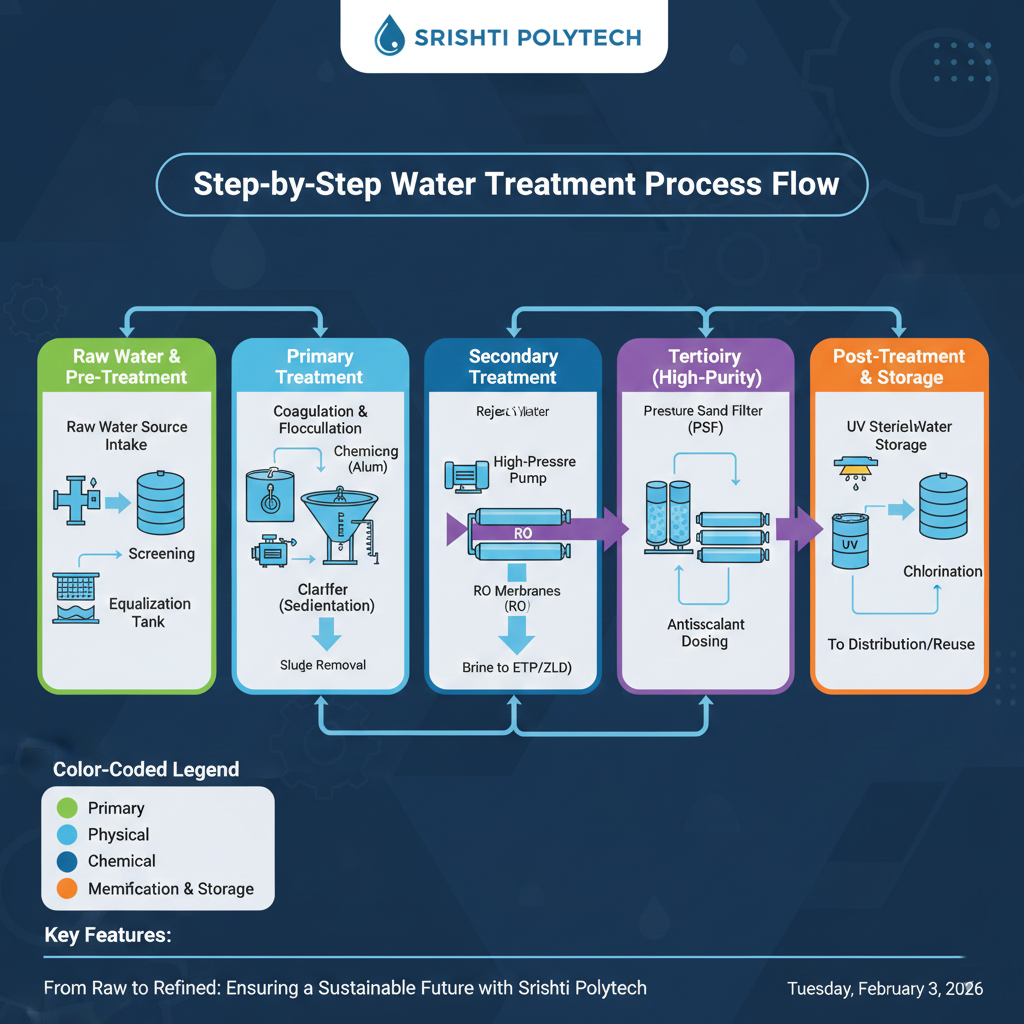

Complete Guide to Water Treatment Plants in India

Feb 03, 2026

uploads/blogs/blog_698195151be73.png

Introduction

Water treatment plants play a critical role in ensuring safe drinking water, compliant industrial discharge, and sustainable water management across India. With rising water scarcity, stricter pollution control norms, and rapid industrialization, water treatment systems such as RO, STP, ETP, Softener, and ZLD have become essential for municipalities, industries, hospitals, hotels, and commercial facilities.

This guide explains types of water treatment plants, processes, applications, regulations, costs, and selection tips—with an India-specific lens.

What is a Water Treatment Plant?

A Water Treatment Plant (WTP) is a system designed to remove physical, chemical, and biological contaminants from raw water or wastewater to make it suitable for drinking, industrial use, reuse, or safe discharge as per regulatory standards.

Types of Water Treatment Plants in India

1. Drinking Water Treatment Plant (DWTP)

Purpose: Make raw water potable.

Typical Process:

Coagulation & Flocculation

Sedimentation

Filtration (Sand/Activated Carbon)

Disinfection (Chlorination/UV/Ozone)

Applications: Municipal water supply, housing societies, institutions.

2. Reverse Osmosis (RO) Plant

Purpose: Remove dissolved salts (TDS), heavy metals, and pathogens.

Process Flow:

Pretreatment → High-pressure RO membranes → Posttreatment

Applications:

Industrial process water

Commercial drinking water

Bottling plants

Hospitals & dialysis centers

Common Capacities: 250 LPH to 1,00,000+ LPH

3. Effluent Treatment Plant (ETP)

Purpose: Treat industrial wastewater before discharge or reuse.

Industries Covered: Textile, pharma, chemicals, food & beverage, tanneries.

Process Stages:

Primary: Screening, equalization, pH correction

Secondary: Biological treatment (Aeration, MBBR)

Tertiary: Filtration, RO, disinfection

4. Sewage Treatment Plant (STP)

Purpose: Treat domestic sewage from buildings and campuses.

Common Technologies:

MBBR

SBR

MBR

ASP

Reuse: Gardening, flushing, cooling towers.

5. Water Softener Plant

Purpose: Remove hardness (Calcium & Magnesium).

Benefits:

Prevents scaling

Improves RO life

Reduces energy consumption

Applications: Boilers, cooling towers, hotels, laundries.

6. Zero Liquid Discharge (ZLD) System

Purpose: Ensure no wastewater discharge.

Includes: ETP + RO + MEE/ATFD

Mandatory For: Highly polluting industries in many Indian states.

Key Components of a Water Treatment Plant

Raw Water Pump

Pressure Sand Filter (PSF)

Activated Carbon Filter (ACF)

Dosing Systems (Antiscalant, Chlorine, pH)

RO Membranes & Pressure Vessels

Control Panel & Instrumentation

Treated Water Storage Tank

Water Treatment Regulations in India

Regulatory Bodies:

Central Pollution Control Board (CPCB)

State Pollution Control Boards (SPCBs)

BIS (IS 10500: Drinking Water Standards)

Compliance Areas:

Effluent discharge norms

Consent to Establish (CTE)

Consent to Operate (CTO)

Environmental Clearance (EC)

Cost of Water Treatment Plants in India (Indicative)

| Plant Type | Capacity | Approx. Cost (INR)

| RO Plant | 1000 LPH | 2 – 4 Lakhs |

| STP | 50 KLD | 6 – 10 Lakhs |

| ETP | 50 KLD | 8 – 15 Lakhs |

| Softener | 1000 LPH | 1 – 2 Lakhs |

Costs vary based on water quality, automation, and materials (FRP/SS).

How to Choose the Right Water Treatment Plant

1. Analyze raw water quality (TDS, hardness, iron, bacteria)

2. Define treated water usage (drinking, reuse, discharge)

3. Select capacity with future expansion in mind

4. Ensure compliance with CPCB/SPCB norms

5. Choose a reliable OEM manufacturer with service support

Why Choose an OEM Manufacturer in India?

Custom-built systems

Better pricing

Faster service & spares

Tender & GeM compatibility

Companies like Srishti Polytech design and manufacture customized water treatment plants for industrial and commercial applications across India.

Future of Water Treatment in India

Atmospheric Water Generation (AWG)

Smart RO systems with IoT

Water reuse & recycling

Energy-efficient membranes

Conclusion

Water treatment plants are no longer optional—they are essential infrastructure for sustainable growth in India. Selecting the right technology, capacity, and OEM partner ensures long-term compliance, cost savings, and environmental responsibility.

Looking for a customized Water Treatment Plant?

Contact Srishti Polytech for RO, STP, ETP, Softener & ZLD solutions across India.

Feb 03, 2026

Complete Guide to Water Treatment Plants in India

Introduction

Water treatment plants play a critical role in ensuring safe drinking water, compliant industrial discharge, and sustainable water management...

What is an RO Plant?

Feb 02, 2026

uploads/blogs/blog_69804c597d52e.png

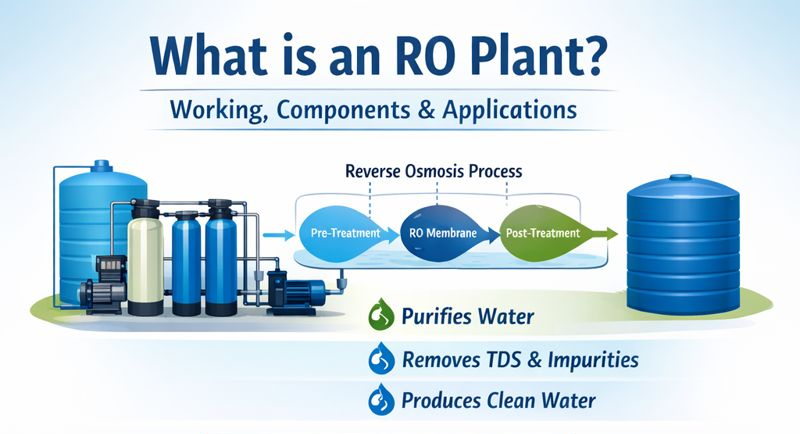

What is an RO Plant?

Working, Components & Applications (Industrial + Commercial)

Clean and safe water is a critical requirement for industries, businesses, and institutions. One of the most widely used water purification technologies today is the RO (Reverse Osmosis) Plant. From factories and hospitals to hotels and schools, RO plants ensure consistent water quality by removing dissolved impurities, salts, and contaminants.

In this blog, we’ll explain what an RO plant is, how it works, its main components, and its industrial & commercial applications.

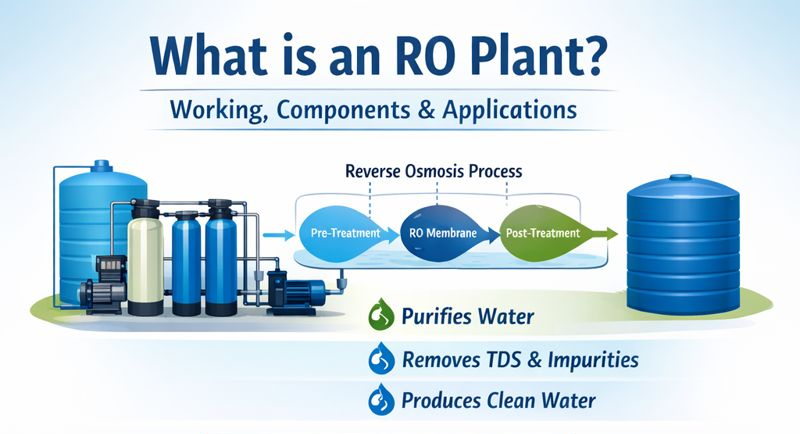

What is an RO Plant?

An RO Plant (Reverse Osmosis Plant) is a water purification system that removes dissolved salts, heavy metals, bacteria, viruses, and other impurities from water by using a semi-permeable membrane.

RO technology works on the principle of reverse osmosis, where pressure is applied to force water through a membrane, allowing only pure water to pass while rejecting contaminants.

RO plants are commonly used for:

* Drinking water purification

* Industrial process water

* Boiler & cooling applications

* Medical and pharmaceutical use

How Does an RO Plant Work?

The working of an RO plant happens in multiple stages to ensure high-quality purified water.

Step-by-Step RO Plant Working Process:

1. Raw Water Feed

* Water from borewell, tanker, or municipal supply enters the system.

2. Pre-Treatment Stage

* Suspended solids, dirt, chlorine, and organic matter are removed to protect the RO membrane.

3. High-Pressure Pump

* Increases water pressure to push it through the RO membrane.

4. RO Membrane Separation

* Pure water passes through the membrane.

* Dissolved salts and impurities are rejected as reject/brine water.

5. Post-Treatment

* pH correction, UV disinfection, or mineral dosing (if required).

6. Treated Water Storage

* Purified water is collected in a storage tank for usage.

Main Components of an RO Plant

An RO plant consists of several critical components that ensure efficient operation:

1. Raw Water Pump

Transfers feed water to the pre-treatment section.

2. Pre-Treatment System

Includes:

* Sand Filter (removes suspended particles)

* Activated Carbon Filter (removes chlorine, odor, color)

* Micron Cartridge Filters (fine filtration)

3. High-Pressure Pump

Provides required pressure to push water through RO membranes.

4. RO Membrane

The heart of the system. Removes:

* TDS (Total Dissolved Solids)

* Heavy metals

* Salts & chemicals

* Bacteria & viruses

5. Membrane Housing

Protects and holds RO membranes safely.

6. Control Panel

Manages system operation, pressure, flow, and safety interlocks.

7. Post-Treatment System

* pH correction dosing

* UV sterilizer (optional)

* Mineral dosing (for drinking water)

8. Product & Reject Water Lines

Separates purified water from reject water.

Industrial Applications of RO Plants

Industrial RO plants are designed for high capacity and heavy-duty usage.

Common Industrial Applications:

* Manufacturing Units

* Boilers & Cooling Towers

* Pharmaceutical & Chemical Industries

* Textile & Dyeing Industries

* Food & Beverage Processing

* Bottling & Packaged Drinking Water Plants

* Power Plants

* Mining & Heavy Industries

Industrial RO plants typically range from 500 LPH to 1,00,000+ LPH, depending on requirement.

Commercial Applications of RO Plants

Commercial RO plants focus on safe drinking water and moderate capacity.

Common Commercial Applications:

* Hospitals & Dialysis Centers

* Hotels & Restaurants

* Schools, Colleges & Hostels

* Offices & Corporate Buildings

* Shopping Malls

* Railway Stations & Airports

* Water ATMs

Commercial RO plants usually range from 250 LPH to 2000 LPH.

Benefits of Using an RO Plant

✔ Removes up to 99% dissolved impurities

✔ Improves taste, odor, and clarity of water

✔ Protects industrial equipment from scaling

✔ Reduces maintenance and operating costs

✔ Ensures compliance with water quality standards

✔ Customizable for industrial and commercial needs

Choosing the Right RO Plant Capacity

Selecting the correct RO plant depends on:

* Raw water TDS level

* Daily water consumption

* Industrial or drinking water usage

* Recovery percentage required

👉 Common capacities:

* 250 / 500 LPH – Commercial use

* 1000 / 2000 LPH – Hospitals, hotels, small industries

* 5000 LPH & above – Large industries

Why Choose Srishti Polytech for RO Plants?

Srishti Polytech is a trusted OEM manufacturer and supplier of RO plants for industrial and commercial applications.

What We Offer:

* Custom-designed RO plants

* High-quality membranes & pumps

* Robust SS/MS skid construction

* Energy-efficient systems

* After-sales service & AMC support

Conclusion

An RO plant is an essential solution for industries and commercial establishments facing water quality challenges. By understanding its working, components, and applications, businesses can make informed decisions for reliable and safe water treatment.

If you are planning to install an Industrial or Commercial RO Plant, Srishti Polytech can provide a tailor-made solution to meet your exact requirements.

Feb 02, 2026

What is an RO Plant?

What is an RO Plant?

Working, Components & Applications (Industrial + Commercial)

Clean and safe water is a critical requirement for industries,...

Effluent Cum Sewage Treatment Plant at Central Hospital Dhori – Srishti Polytech

Jan 12, 2026

uploads/blogs/blog_6964ab7ce9598.jpeg

Effective wastewater management is essential for hospitals and public infrastructure to protect public health and the environment. Srishti Polytech, a leading water treatment solution provider in India, has successfully designed, installed, and commissioned a 20 KLD Sewage Treatment Plant (STP) at Regional Hospital, Dhori Area, Jharkhand.

This project reflects Srishti Polytech’s commitment to delivering reliable, eco-friendly, and regulatory-compliant water treatment solutions for healthcare institutions.

Project Overview

The 20 KLD STP at Central Hospital Dhori has been developed to treat hospital sewage efficiently, ensuring safe disposal and reuse of treated water. Hospital wastewater requires specialized treatment due to the presence of organic waste, chemicals, and pathogens.

Project Details

Location: Central Hospital, Dhori Area, Jharkhand

Capacity: 20 KLD (Kilo Liters per Day)

Plant Type: Effluent Cum Sewage Treatment Plant (STP)

Application: Hospital wastewater treatment

Execution: Complete turnkey solution by Srishti Polytech

Importance of Sewage Treatment in Hospitals

Hospital wastewater, if untreated, can cause serious environmental and health hazards. A properly designed STP helps in:

Preventing groundwater and soil contamination

Meeting pollution control board guidelines

Improving sanitation and hygiene standards

Reducing environmental impact

Supporting water reuse for non-potable purposes

STP Process & Technology

The 20 KLD STP installed at Dhori Hospital uses a well-engineered treatment process to ensure consistent output quality.

Treatment Stages

1️⃣ Preliminary Treatment

Screening to remove solid waste

Grit removal to protect downstream equipment

2️⃣ Primary Treatment

Flow equalization

Settling of suspended solids

3️⃣ Secondary (Biological) Treatment

Effective reduction of BOD & COD

Biological breakdown of organic pollutants

4️⃣ Tertiary Treatment

Filtration and disinfection

Treated water suitable for reuse or safe discharge

Environmental Benefits

The installation of this STP delivers multiple environmental and social benefits:

🌱 Protection of natural water resources

💧 Water conservation through reuse

🏥 Cleaner and safer hospital surroundings

🌍 Contribution to sustainable development goals

Inauguration & Project Significance

The inauguration of the 20 KLD Sewage Treatment Plant at Central Hospital Dhori highlights the growing focus on sustainable infrastructure in public healthcare facilities. The project stands as a model for efficient wastewater management in hospitals across Jharkhand.

Why Choose Srishti Polytech?

Srishti Polytech is a trusted name in water and wastewater treatment solutions, offering customized systems for hospitals, industries, and government institutions.

Our Key Strengths

✔ Expertise in STP, ETP & RO Plants

✔ Turnkey project execution

✔ Robust design and quality fabrication

✔ Compliance with CPCB & SPCB norms

✔ Reliable after-sales support

✔ Proven track record in Jharkhand & PAN India

Applications of Our Water Treatment Solutions

Hospitals & medical institutions

Residential apartments & townships

Hotels & commercial buildings

Industrial units

Government and municipal projects

Conclusion

The 20 KLD Sewage Treatment Plant at Central Hospital Dhori demonstrates how efficient wastewater treatment can support environmental protection and public health. Through this project, Srishti Polytech continues to strengthen its position as a reliable water solution partner in India.

For STP, ETP, RO plants, and complete water management solutions, Srishti Polytech delivers performance you can trust.

Contact Srishti Polytech

🌐 Website: www.srishtipolytech.com

📍 Service Area: Jharkhand | Dhanbad | Bokaro | Ranchi | PAN India

💧 Solutions: STP | ETP | RO Plant | Industrial Water Treatment

Jan 12, 2026

Effluent Cum Sewage Treatment Plant at Central Hospital Dhori – Srishti Polytech

Effective wastewater management is essential for hospitals and public infrastructure to protect public health and the environment. Srishti Polytech, a...

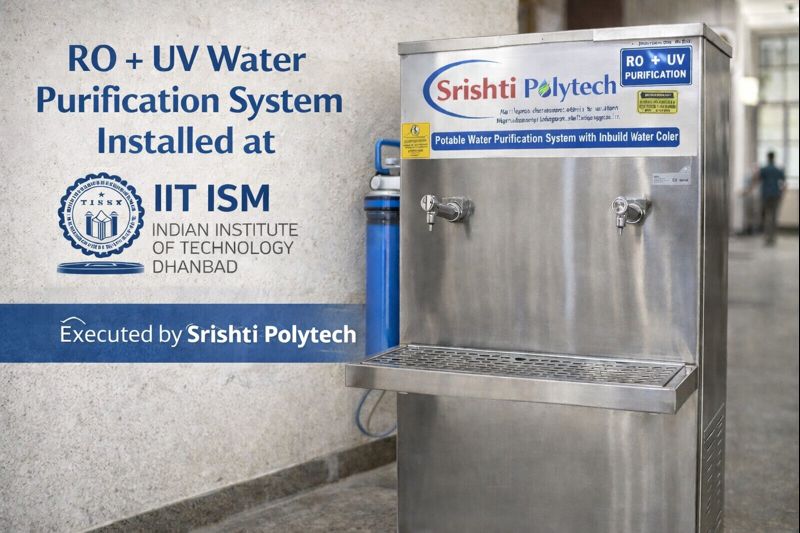

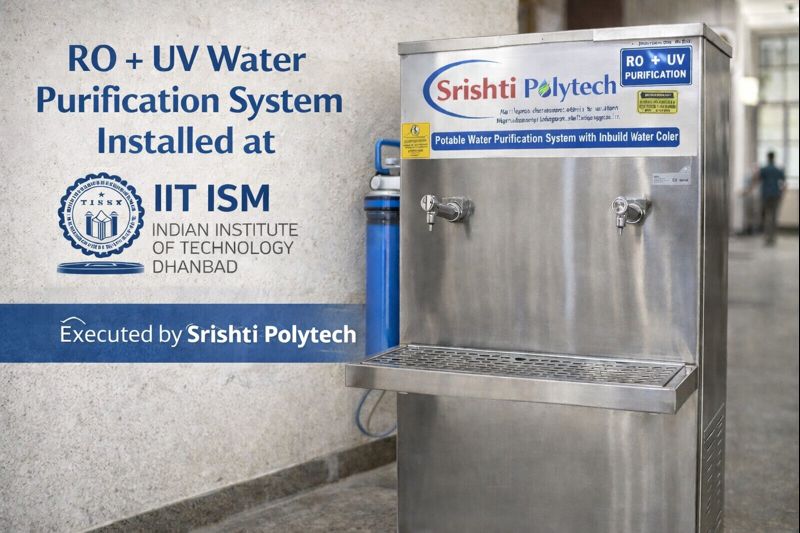

RO + UV Water Purification Project at IIT (ISM) Dhanbad

Dec 29, 2025

uploads/blogs/blog_69524b89e63ef.png

Government Institutional Drinking Water Solution by Srishti Polytech

Srishti Polytech, a Dhanbad-based OEM and trusted water treatment solution provider, successfully executed a RO + UV potable water purification system project at IIT (ISM) Dhanbad through the Online CPP e-Procurement Portal (Central Public Procurement Portal – CPPP). This project reflects our capability to deliver government-compliant drinking water solutions for premier educational institutions in India.

Project Overview

IIT (ISM) Dhanbad, an Institute of National Importance, requires reliable and hygienic drinking water infrastructure to serve students, faculty, and staff. Under this project, Srishti Polytech supplied and commissioned a Potable Water Purification System with Inbuilt Water Cooler, designed specifically for institutional and continuous usage.

The entire procurement and execution process was carried out through the Online CPP e-Procurement system, ensuring transparency, compliance, and adherence to Government of India procurement norms.

Scope of Work

As part of this CPP e-procurement project, Srishti Polytech was responsible for:

Supply of RO + UV based potable water purification system

OEM-manufactured equipment with verified specifications

SS304 stainless steel body and storage tank for hygiene and durability

Installation, testing, and demonstration

Documentation and handover as per institutional and CPP guidelines

Execution Through Online CPP e-Procurement Portal

This project was executed through the Central Public Procurement Portal (CPPP), highlighting Srishti Polytech’s strong understanding of government tendering processes and compliance requirements. Our ability to meet technical specifications, delivery timelines, and service obligations makes us a reliable partner for CPP-based government projects.

Importance of the Project for IIT (ISM) Dhanbad

The installed RO + UV water purification system ensures:

Safe and hygienic drinking water for campus users

Reduced dependency on packaged drinking water

Compliance with government health and safety norms

Sustainable and cost-effective water management

Such projects contribute directly to improving campus infrastructure and student welfare.

Why Government Institutions Choose Srishti Polytech

OEM manufacturing with strict quality control

Proven experience in CPP and government projects

Compliance with IS standards and procurement norms

Strong service presence in Jharkhand and Eastern India

Timely installation and responsive after-sales support

Conclusion

The successful completion of the RO + UV water purification project at IIT (ISM) Dhanbad through Online CPP e-Procurement reinforces Srishti Polytech’s position as a trusted government water treatment solution provider. We remain committed to supporting educational institutions and public sector organizations with reliable, compliant, and efficient drinking water solutions.

For government tenders, institutional projects, and water treatment solutions, visit: 👉 www.srishtipolytech.com | www.srishtipolytech.in

Dec 29, 2025

RO + UV Water Purification Project at IIT (ISM) Dhanbad

Government Institutional Drinking Water Solution by Srishti Polytech

Srishti Polytech, a Dhanbad-based OEM and trusted water treatment solution provider, successfully executed...

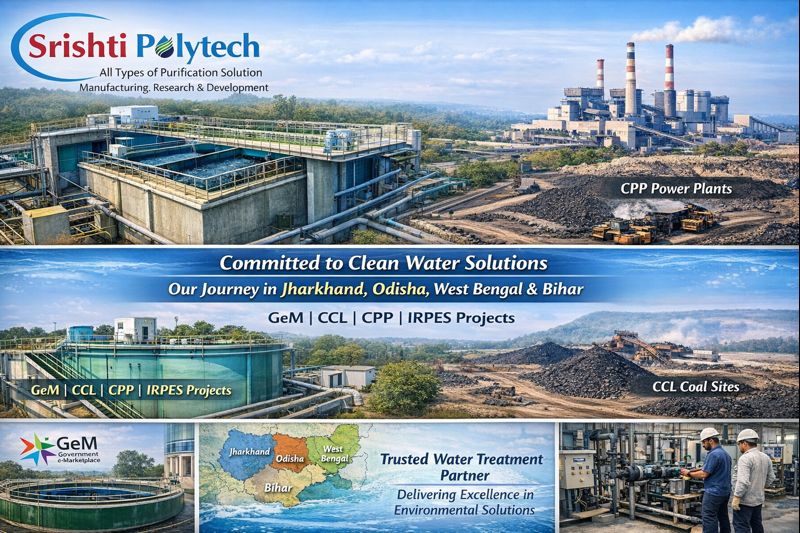

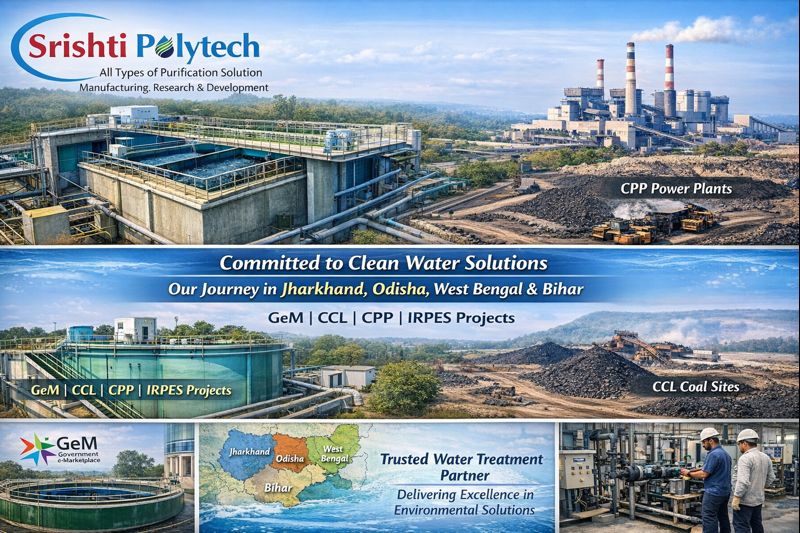

Government Water Treatment & ETP Projects | Srishti Polytech

Dec 29, 2025

uploads/blogs/blog_69520123e9dfa.png

Our Journey in Government Water Treatment Projects

Srishti Polytech: Delivering Reliable Water Treatment Solutions Across Eastern India

Clean water and responsible wastewater management are critical for sustainable development. Srishti Polytech, based in Dhanbad, Jharkhand, has been on a focused journey to support government and public sector organisations with water treatment solutions, Effluent Treatment Plants (ETP), and Operation & Maintenance (O&M) services. Over the years, we have successfully partnered with multiple government bodies and PSUs through platforms like GeM, CCL, CPP, and IRPES, delivering dependable and compliant solutions across Jharkhand, Odisha, West Bengal, and Bihar.

Our Journey: From Manufacturing to Government Projects

Srishti Polytech began as an OEM (Original Equipment Manufacturer) with a clear vision: to design, manufacture, and execute water treatment systems that meet Indian standards and real-world site conditions. What started with RO plants and water treatment equipment soon expanded into large-scale ETP projects, industrial water treatment, and annual operation & maintenance contracts for government institutions.

Our growth has been driven by:

Strong in-house technical expertise

Compliance with government norms and tender requirements

Timely execution and transparent communication

Long-term performance through structured O&M services

Government & PSU Projects We Serve

Srishti Polytech actively works with central and state government departments, PSUs, hospitals, educational institutions, and industrial units. Our experience includes projects executed through:

GeM (Government e-Marketplace)

We are a registered and active supplier on GeM, providing water treatment plants, ETP systems, spares, and O&M services as per tender specifications and timelines.

CCL (Central Coalfields Limited)

In mining-intensive regions, wastewater and effluent management is crucial. We support CCL with customized ETP solutions and maintenance services designed for high-load and challenging site conditions.

CPP (Captive Power Plants)

For CPP units, we deliver water and effluent treatment systems that ensure compliance with pollution control norms while maintaining operational efficiency.

IRPES & Other Engineering Systems

Through IRPES and allied platforms, we contribute to government engineering and infrastructure projects by supplying reliable treatment systems and long-term support.

Core Services Offered by Srishti Polytech

Effluent Treatment Plants (ETP)

We design, manufacture, install, and commission ETP plants for hospitals, industries, mining units, and government facilities. Our ETP solutions are tailored to meet CPCB and SPCB norms, ensuring safe discharge and reuse of treated water.

Operation & Maintenance (O&M)

A water treatment system is only as good as its operation. Our O&M services ensure:

Consistent performance

Reduced downtime

Optimised chemical and power consumption

Extended plant life

We offer AMC and comprehensive O&M contracts for government and PSU clients.

Turnkey Water Treatment Solutions

From site survey and design to installation and handover, we provide end-to-end water treatment solutions backed by documentation, training, and after-sales support.

Regional Presence: Four Key States

Jharkhand

With our base in Dhanbad, Jharkhand remains a core focus area. We actively serve mining regions, hospitals, and government institutions with ETP and water treatment solutions.

Odisha

In Odisha, we support healthcare facilities, industrial units, and government departments with compliant and efficient water treatment systems.

West Bengal

Our projects in West Bengal include water and wastewater treatment plants for public sector units and infrastructure-related facilities.

Bihar

In Bihar, we contribute to improving water quality and wastewater management through customised treatment solutions and reliable O&M services.

Why Government Bodies Trust Srishti Polytech

OEM capability with quality-controlled manufacturing

Proven experience in government and PSU projects

Compliance with tender, safety, and environmental norms

Prompt service support and transparent reporting

Focus on sustainability and long-term performance

Looking Ahead

As water scarcity and environmental regulations continue to grow in importance, Srishti Polytech remains committed to supporting government initiatives with innovative and dependable water treatment solutions. Our future roadmap includes advanced treatment technologies, improved automation, and sustainable water reuse systems for public infrastructure projects.

Partner with Srishti Polytech for trusted government water treatment solutions across Jharkhand, Odisha, West Bengal, and Bihar.

For enquiries and project discussions, visit www.srishtipolytech.com.

#SrishtiPolytech #GovernmentProjects #WaterTreatment #ETPPlant #OandMServices #GeM #CCL #CPP #IRPES #Jharkhand #Odisha #WestBengal #Bihar

Dec 29, 2025

Government Water Treatment & ETP Projects | Srishti Polytech

Our Journey in Government Water Treatment Projects

Srishti Polytech: Delivering Reliable Water Treatment Solutions Across Eastern India

Clean water and responsible wastewater...

10 KLD ETP Plant at Bolani Hospital, Odisha | Srishti Polytech

Dec 24, 2025

uploads/blogs/blog_694b9e96b0431.png

Srishti Polytech successfully installed a 10 KLD Effluent Treatment Plant at Bolani Hospital, Odisha, ensuring safe and compliant hospital wastewater treatment as per CPCB norms.

Srishti Polytech has successfully designed, supplied, installed, and commissioned a 10 KLD Effluent Treatment Plant (ETP) at Bolani Hospital, Odisha, ensuring safe and eco-friendly treatment of hospital wastewater in compliance with CPCB and SPCB norms.

The 10 KLD ETP plant is specially engineered to treat hospital effluent, which contains organic load, chemicals, detergents, and biological contaminants. The system efficiently removes BOD, COD, TSS, oil & grease, and pathogens, making the treated water suitable for safe discharge or reuse for non-potable applications.

Key Features of the 10 KLD ETP Plant

Compact and space-saving design suitable for hospital premises

Automated chemical dosing system for consistent performance

High-efficiency Primary, Secondary, and Tertiary Treatment Process

Low power consumption and easy operation

Minimal maintenance with long service life

Designed as per CPCB / SPCB hospital wastewater guidelines

Process Flow of Hospital ETP

The installed hospital effluent treatment plant includes:

Collection & Equalization Tank

Chemical Dosing (Acid, Alkali, Coagulant, Flocculant)

Primary Clarification

Pressure Sand Filter (PSF)

Activated Carbon Filter (ACF)

Sludge Handling System

This 10 KLD ETP system ensures reliable performance and supports environmental sustainability by reducing pollution load and protecting nearby water bodies.

Trusted ETP Manufacturer in Odisha

With this successful installation at Bolani Hospital, Srishti Polytech reinforces its position as a leading ETP plant manufacturer and supplier in Odisha and Eastern India. Our customized wastewater treatment solutions are widely used in hospitals, industries, hotels, institutions, and commercial establishments.

Dec 24, 2025

10 KLD ETP Plant at Bolani Hospital, Odisha | Srishti Polytech

Srishti Polytech successfully installed a 10 KLD Effluent Treatment Plant at Bolani Hospital, Odisha, ensuring safe and compliant hospital wastewater...